MRO Multi Roll Opener

Ideal for:

- viscose

- bleached cotton

- crimped fibers

New features of our MRO:

- 3000 mm wide

- only 5,5 kW suction needed

- 1500 kg/ h

- roll-on/ roll-off for cylinders

- easy access to the opening sections

- h-type sealing of cylinder ends

- optional eliminating of hard pieces

- drives with frequency inverters

- Siemens PLC, SEW drives

What is clampless opening?

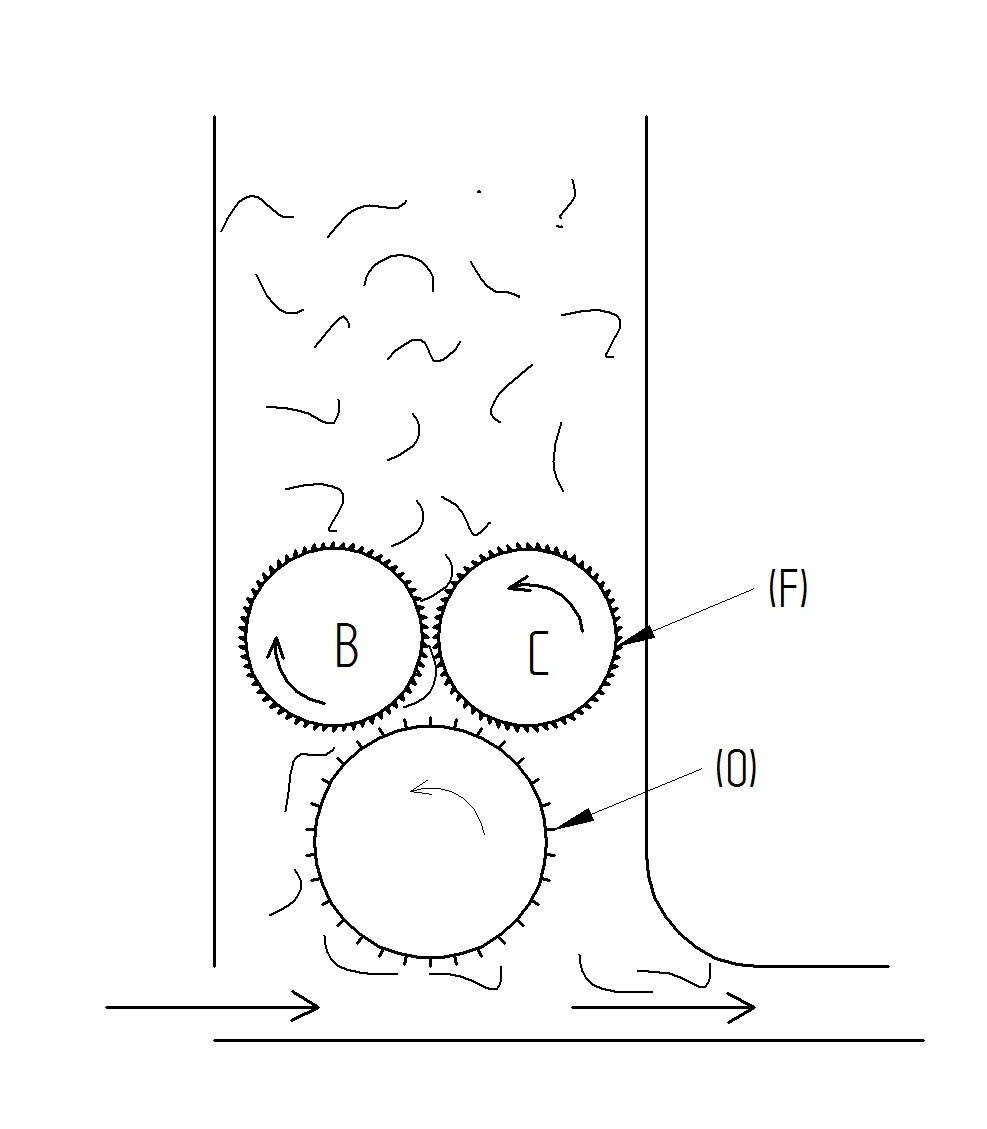

Normal clamped opening works as follows:

Material is slowly fed by a pair of feeding rollers (F) to a fast turning opening roller (O). The fibers are dragged out of the feeding and thereby opened. The opened fibers get to another opening roller or are air-doffed by an air stream. Instead of 2 feed rollers,also a feed roller and feed plate arrangement can be used. This works well for fibers that are easy to open. Fibers that stick together or come in packages (from crimping process) are further pressed together and these further compressed bundles are drawn from the feed arrangement as one package.

Hard pieces or metal are pressed in the direction of the opening roll and cause damage or are further transported.

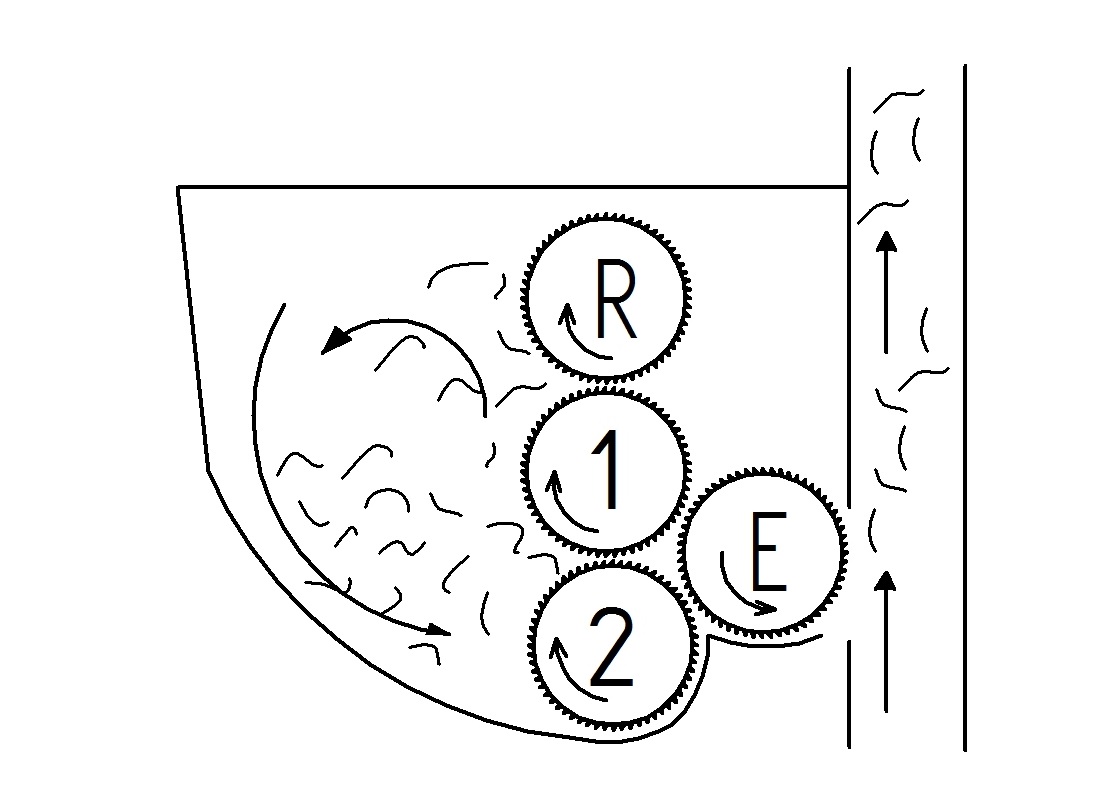

The unclamped opening works very differently:

The fiber is presented in loose form on a slide or apron to 2 opening cylinders. The fibers are caught by the wire of opening cylinder 1) and transported to the gap between opening cylinder 1) and 2). The opening is done between the wire of opening cylinders 1) and 2) in the gap. Opening cylinder 2) runs faster than opening cylinder 1). By this, big pieces, that cannot pass the gap, are kicked back to the slide. Fibers that cannot pass are taken by opening cylinder 2) to the gap between opening cylinder 2) and the return cylinder R). Those fibers that get opened pass the gap, everything else is thrown back to the slide and presented again. Things that cannot be opened and are bigger than the gap cannot pass the opening. Rather than pressing and trying to open all at one passage, the repeated action of the MRO for fibers that are stuck together gives a gentle and uniform opening effect.

Easy opening fibers pass the machine at the first attempt, agglomerations of fibers are opened in multiple turns.

An extraction roll (E) takes the opened fibers from the opening cylinders (O1 + O2) and transfers them to an air stream.

Though the MRO is an expensive opening machine, it is a must for bleached cotton,

viscose, crimped or fused fibers or contaminated material.

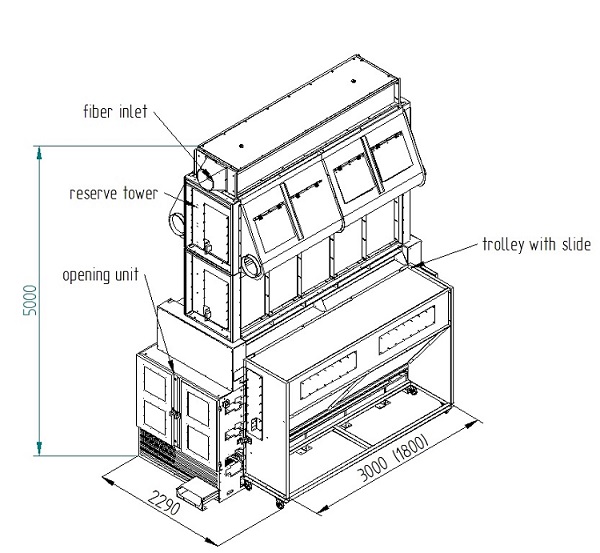

The picture below provides an overview of the most important components and assemblies and shows where they are installed on the machine.

Reserve tower

Fibers and air blown into a tower are separated at electrolytically polished stainless steel sieves. The fibers settle in the tower. The transport air passes through holes in the sieves and is sucked by the filter. To compensate varying air quantities blown to the tower, a false air opening is on the opposite side. The suction volume can be set by an air regulator in the suction tube.

The regulator should be set so that still a small false air will be sucked when maximum air is blowing into the machine.

The fibers settle in the reserve tower. A pair of feed rolls feeds the fiber to a coarse opening roll. To avoid a blow through at the tower, a minimum level light barrier stops the feed rolls.

Background information: History of the MRO

Background information: What is the difference in the carding action of a worker and stripper and the action at the MRO?