MRO Multi Roll Opener

What is the difference in the carding action of a worker and stripper and the action at the MRO?

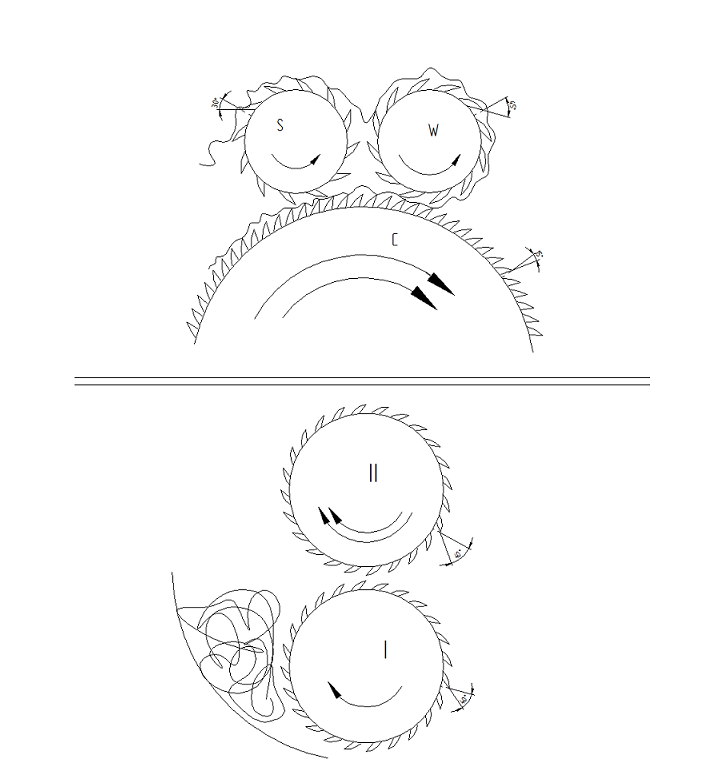

In a card the main cylinder carries the fibers with high speed to the worker. The worker rotates at significantly lower speed at the carding point in the same direction as the main cylinder.

Therefore, all fibers are squeezed into the nip between worker and cylinder.

This results in a brutal handling of bigger lumps and a damage to the wire when hand pieces find their way.

In the MRO the two identic wire-wound rolls rotate in the same direction, this resulting in a surface speed in opposite direction at the carding point.

As the speed of the upper cylinder is faster than the lower cylinder that presents the fibers to the upper, fiber agglomerations or foreign material is not allowed to pass the nip point and is kicked back.

By this, the fibers are handled very gently and a uniform opening is achieved. Hard and bulky foreign matter is rejected and can be eliminated at a grill near the slide.