LiRa (linear to random)

LiRa stands for linear to random.

First, a web is made, then destroyed, and then a new web is made.

With the LiRa system uniform low gsm webs with about 1:1 MD/ CD can be achieved. To understand the new process, let's have a look at the previous technology:

Cards with doffer produce webs that are orientated in machine (production run) direction. In a carding machine, the fibers are not carded uniformly. The fiber passage is patchy (like a cow skin). The important step is the doffer. Normal fiber transfer is from slower to higher surface speed, but the doffer has a surface speed of only 10 % (can vary a lot) of the preceding cylinder. Because the wire of the doffer is much more aggressive (~ 45° versus 15°), the fibers pass from the cylinder to the doffer. but on places where the doffer wire is occupied by fibers, no additional fibers can be transferred. The surplus fibers travel further rounds with the cylinder until there is a free place at the doffer. By this, out of a patchy fiber stream a uniform web is built. When the fibers are caught with the "head" in the doffer wire, the "tail" of the fiber is carried a little further by the cylinder. By this, the fibers are orientated in machine direction. As the filling capacity of the doffer wire is limited, the gsm at the doffer is between 15 to 80 gsm max. In order to get more strength or orientation in cross direction, two processes are used:

1) Stuffer rolls

The stuffer rolls act like further doffers. The fibers are transferred into wired cylinders with slower surface speed. By this action, the gsm is increased and the fibers pushed to the side.

2) Random roller

The random roller takes fibers from the last carding cylinder and the transport is in opposite direction and higher speed. In the transfer area, there is a revolving air that randomizes the fibers. The staple length of fibers that can be used for this process is limited and the construction effort is demanding. MD:CD of 2:1 can be reached.

In the aerodynamic process the patchy fibers from the last cylinder are directed on a suction sieve. This results in low gsm webs being very irregular, with holes and thick spots. The regulating effect of the doffer is not there. When the web is 100 gsm and higher, the web gets more uniform as light and heavy tufts rest in about the same spot.

The aerodynamic webs usually have a MD:CD of about 1:1.

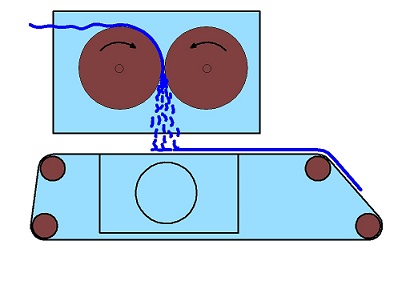

The LiRa system combines the benefit of the doffer with the aerodynamic web orientation. The uniform low gsm web of a doffer is used to have an optimal opening and distribution of fibers. This web is opened up to individual fibers or micro tufts that are immediately sucked to a sieve to make a random web. The gsm can be low as the fibers are uniformly presented and well opened. If the sieve is moved very slowly, also high gsm like up to 200 gsm can be achieved with excellent quality but the interesting market is low gsm with MD:CD of about 1:1.

The system is very simple: a cylinder presents the web to the opening device. The opening device can be an air knife, but it is more energy-efficient to use a high speed cylinder with a special wire to open the web. On a suction belt the web is built like an aerodynamic web. As the high speed cylinder throws the fibers onto the belt, only a mild suction is necessary to secure the fibers to the belt. Delivery roll and suction belt are servo-driven, the high speed cylinder is driven by a frequency inverter.

This system gets better MD/ CD values and eliminates complicated random rolls and condensing rolls. The system can easily be switched from linear to random and for a wide range of random web weights.

As a doffer is involved, the production is limited to the capacity of the doffers.

The LiRa unit works as a stand-alone being fed by a web on a belt or can be integrated into the Compact Card. When conventional cards have to be upgraded to the LiRa system, the unit (delivery roll and high speed roll) has to be placed following the existing delivery roll as the web comes from under the axis of the delivery roll.

Old cards can be upgraded.