OPTiCRAC

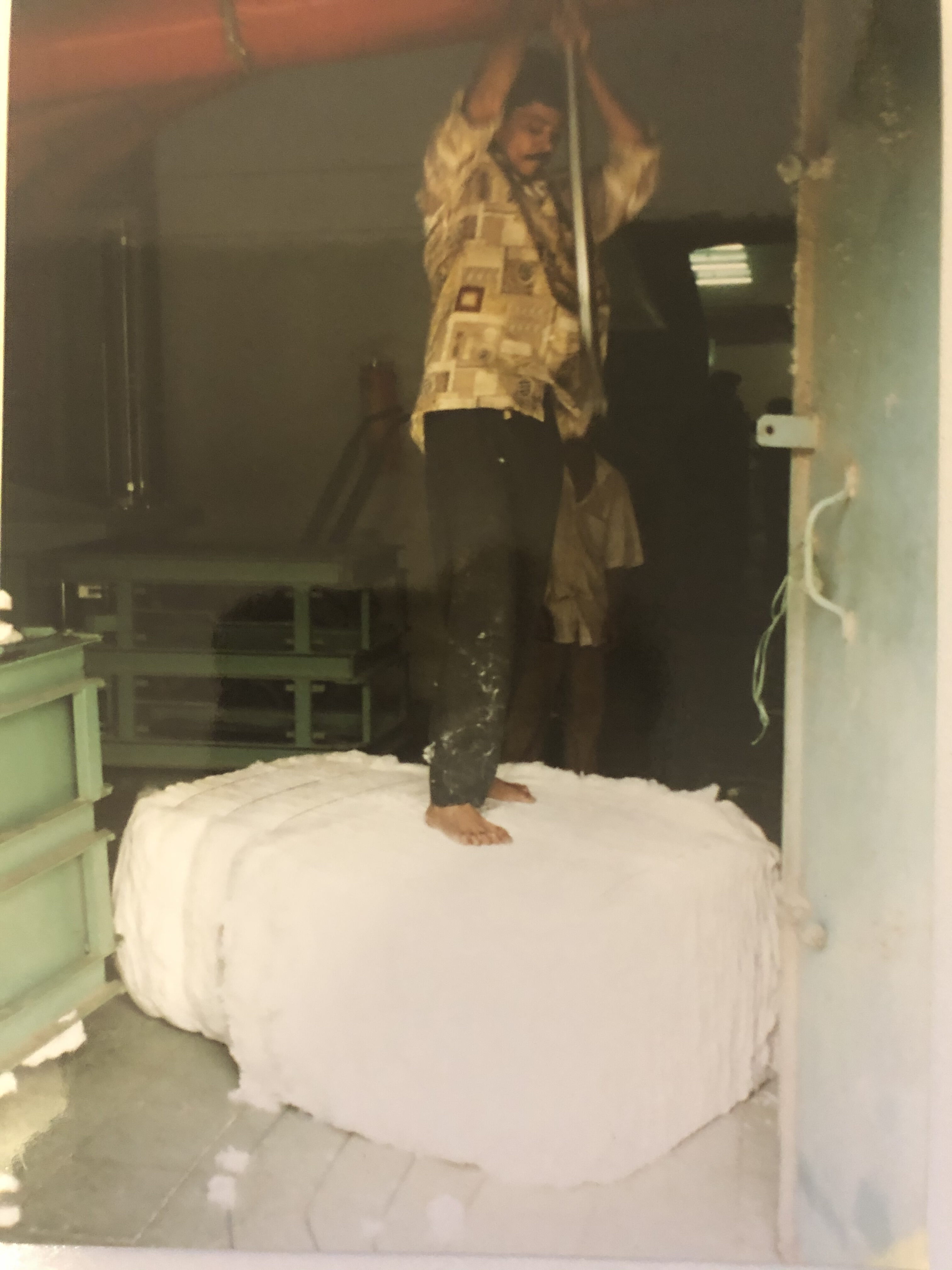

The opening of pressed raw material bales is one of the most dangerous and laborious jobs in the mill. To break open the bale straps a worker has to split the straps or wires using an axe or crowbar. This often leads to injuries, especially with the more frequently used high density bales.

The OPTiCRAC offers:

- Working safety: During the opening process the operator sits protected in the fork-lift. The machine is equipped with safety bars and emergency stops. In stand-by mode or between the bale straps no energy is stored in the cutting unit. The machine is equipped with noise absorbers.

- Speed: The automatic cutting of a whole bale is done in 8 - 10 seconds.

- Work reduction: The handling of a heavy axe or the laborious cutting with a crowbar is eliminated.

- Better bale cleaning: The difficult arduous task of opening the bale is done by the machine, the operator has more time and energy to clean and inspect the bale.

- Low costs: The machine is of simple rugged construction with low power consumption, no hydraulics are used. The low cost replaceable cutting knife is manufactured from special steel. A proven standard industrial computer control is used.

- Flexible operation: The pulse method of strap cutting has proven superior over a wide variety of bales.

- Staff reduction: The use of OPTiCRAC with rotating bale clamp and support elements enables the bales to be arranged and laid by one person.

The process is explained as follows:

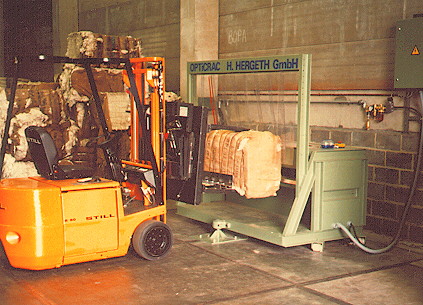

The bale is taken and driven to the OPTiCRAC. The fork lift presses the bale against the OPTiCRAC. The machine is automatically aligned to the bale by a pivot mounting. The two safety panels must be pressed with a force of over 72 kg to start the opening process. A carriagem which is tracked inside the machine, drives along the bale. On the carriage the sensor and the cutting unit are mounted. The radar-like sensor detects the strap or wrappings. A computer processes the signals of the sensor and controls the cutting unit. The unit is triggered when the cutting knife is precisely opposite the bale strap or wire.

Conventional way of opening

Opens bales safely and quickly

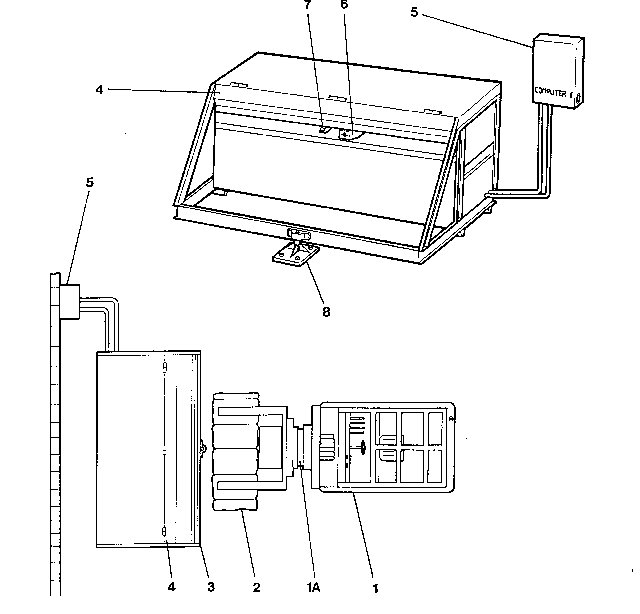

Description

- Fork lift truck with rotating bale clamp 1A

- Bale - The bale is presented to the bale strap cutter

- Bale strap cutter

- Safety Bar (only activates cutter with 72 kg pressure)

- Computer activates sensor

- Sensor detects strap and activates cutting knife

- Cutting knife is pulsed to cut strap

- Pivot mounting to allow automatic alignment

Advantages

- SAFETY - Operator

- SPEED - 8 - 10 seconds a bale

- LABOUR - Reduces man power

- MECHANICAL SIMPLICITY - Ensures operating simplicity and reliability